Protect yourself and your loved ones from viruses, bacteria, fungi and even unpleasant smells. IMUDIS is an effective and safe way to disinfect air and surfaces without the use of any disposable filters or chemicals.

Traditional UV disinfection devices have two major drawbacks: closed devices are not as efficient at disinfecting air as open devices, while open devices can only be used when people are not around, since long exposure to UV rays can damage the eyes and skin. IMUDIS combines these types of devices into one and solves major drawbacks of both.

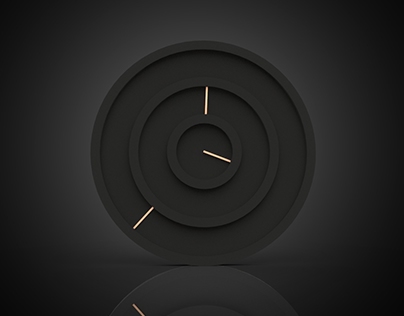

IMUDIS is a smart, multi-functional UV disinfection device that combines air and surface disinfection solutions into one product. During the working day, IMUDIS uses UV-C rays to disinfect the air in your space. When people leave, an autonomous mechanism automatically opens the flaps so that the lamps can disinfect the surfaces directly. When somebody enters the room, the flaps are automatically closed again. This solution allows the use of fewer lamps and fewer devices while achieving a higher level of disinfection.

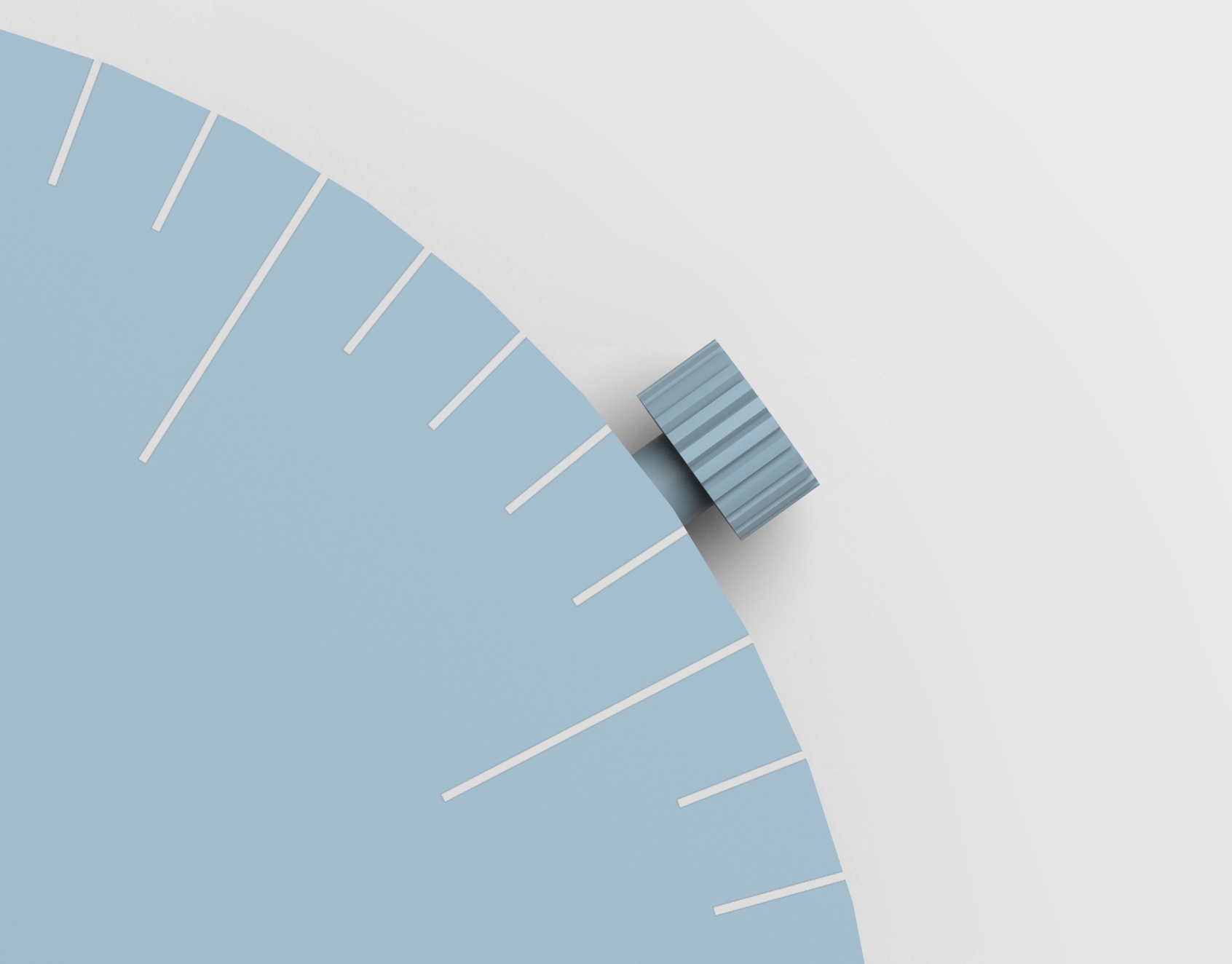

The IMUDIS housing is made of recycled extruded aluminum. Extrusion allows us to produce devices in several different sizes to accommodate different UV-C lamps without making big changes to the manufacturing processes. The aluminum housing also acts as a reflector inside the device, contributing to the effectiveness of disinfection. The housing is made of sustainable and recyclable materials: aluminum and steel.

We began the design process by exploring multiple options of the opening mechanism. Important criteria for the decision were aesthetics, ease of manufacturing and good light coverage when open. A simple mechanism with two flaps was eventually selected, since it allowed us to have all the hinges manufactured in the process of aluminium extrusion, thus having fewer components overall and reducing assembly time.

Manufacturing with aluminium extrusion allows us to produce devices in several different sized without making any big changes to the manufacturing process. Aluminium is an infinitely recyclable material, and it takes up to 95 percent less energy to recycle it than to produce primary aluminum, which also limits emissions, including greenhouse gases. Today, about 75 percent of all aluminum produced in history, nearly a billion tons, is still in use. Our partners in Sweden take this even a step further using mostly emission free hydroelectric power for production of aluminium extrusions.

Over multiple design iterations, testing and market research we have settled on the final form for the device, which is not only aesthetically more pleasing as compared to the competition, but is also simple to manufacture, assemble install and maintain.

The product is undergoing a testing phase.

IMUDIS is part of "Design wings" - a project of non-financial support that brings together talents, knowledge and experience to create design products and services that are competitive and based on the principles of innovation and the digital and circular economy.

Designed by Lukas Avėnas

With the help and support from Denis Orlenok